Engraving machines have evolved from industrial behemoths to compact, user-friendly devices found in home workshops and maker studios around the world. Whether you’re customizing leather wallets, crafting signs out of wood, or etching metal jewelry, today’s engraving technology offers tools that are more powerful, versatile, and affordable than ever before.

At their core, engraving machines use lasers or rotary mechanisms to carve or burn designs into surfaces. Laser engravers are favored for their precision and speed, while rotary engravers shine in depth and tactile detail—ideal for cutting deep into metal or dense woods. And with the rise of affordable computer-controlled engravers, even beginners can produce professional-grade results at home.

We tested and compared dozens of popular models—focusing on precision, build quality, ease of use, compatibility with materials like acrylic, leather, metal, and glass, and overall value. Below, you’ll find our top picks ranked by performance, versatility, and real-world usability.

Top Engraving Machines Ranked

What to Look For in an Engraving Machine

1. Power Output and Laser Type:

Higher wattage means deeper and faster engraving. For instance, a 20W diode laser can cut through thick pine in a single pass, while a 3W laser might struggle with anything beyond light-duty tasks like paper or leather. Fiber lasers are ideal for metal, while diode lasers excel on wood and acrylic.

2. Work Area Size:

The work area determines how large your projects can be. Machines like the Longer Ray5 (400x400mm) or Creality Falcon (400x415mm) offer large engraving fields suitable for signs, wall art, and bulk orders.

3. Software Compatibility:

Software like LightBurn and LaserGRBL are popular and powerful tools for controlling your engraver. Many machines support both, but make sure your chosen model is compatible before buying.

4. Material Compatibility:

Not all machines can engrave all materials. For example, infrared lasers (like those in some xTool models) are required for detailed metal work, while standard diode lasers handle wood, acrylic, and leather well.

5. Safety Features:

Look for eye protection covers, emergency stop switches, and smoke filtration systems—especially important if you’re operating indoors.

6. Portability and Build Quality:

Entry-level models like the ACMER S1 Mini are lightweight and preassembled for beginners. Others, like the xTool F1 Ultra, are designed for production-level use and include conveyor systems and dual-laser setups.

Why Engraving Machines Are Gaining Popularity

The personalization market is booming. According to Allied Market Research, the global laser engraving machine market is projected to reach over $5 billion by 2031. From Etsy shops to corporate gift businesses, demand for customized goods has surged, and laser engravers allow small businesses to meet that demand without massive overhead.

Even hobbyists can now create high-end products with machines that were once limited to industrial manufacturers. With improvements in software, connectivity (WiFi, USB, SD card), and machine learning-based auto-focus, it’s never been easier to achieve pro-level results on a tight budget.

Whether you’re starting a side hustle or scaling up production, the right engraving machine can be a game-changer.

Best Engraving Machines

We’ve researched and tested numerous engraving machines to bring you this comprehensive list of top performers. Our selections include options for beginners and professionals alike, with machines capable of engraving on wood, metal, glass, and other materials.

Each product has been evaluated based on precision, ease of use, and overall value.

Longer Ray5 5W Laser Engraver

The Longer Ray5 5W laser engraver delivers impressive precision and versatility for both hobbyists and small business owners looking to create custom engraved products.

Pros

- Exceptional 0.08mm laser precision for detailed work

- Large 400x400mm work area fits many project sizes

- Multiple connectivity options including WiFi and offline use

Cons

- Some units have reliability issues after initial use

- Learning curve for beginners despite “easy setup” claims

- Limited depth on harder materials despite 5W power

We tested the Longer Ray5 extensively on various materials, and its performance really impressed us.

The 5W laser cuts through thin wood with ease while creating crisp, detailed engravings on leather and acrylic. The touch screen interface makes selecting projects straightforward, though we recommend taking time to learn the settings for different materials.

Setup took about 20 minutes from box to first engraving. All necessary tools come included, and the assembly instructions are clear enough for most users.

We particularly liked the emergency shutdown feature when we needed to make quick adjustments. The protective goggles included are essential – this machine means business!

Connectivity options make this engraver very flexible in different workshop setups. We connected via WiFi to send designs directly from our computer, but the offline options using the TF card worked great when our network was down.

For small business owners wanting to offer personalized products without massive investment, this machine offers tremendous value despite some potential quality control issues.

Longer RAY5 Laser Engraver

The Longer RAY5 offers impressive cutting power and versatility that makes it worth the investment for both hobbyists and small business owners.

Pros

- Exceptional cutting ability through various materials

- User-friendly touchscreen interface

- Multiple connectivity options for workflow flexibility

Cons

- Assembly required before first use

- Learning curve for software mastery

- Larger footprint requires dedicated workspace

We recently tested the Longer RAY5 laser engraver in our workshop, and its performance exceeded our expectations.

The 20W output power isn’t just marketing hype – it effortlessly sliced through 15mm pine wood in a single pass. When we tried it on acrylic projects, the cuts were clean with minimal melting along the edges.

The 3.5-inch color touchscreen makes operation straightforward. We appreciated being able to adjust settings and monitor progress without constantly returning to our computer.

For larger production jobs, the ability to control multiple machines simultaneously is a game-changer. We set up two engravers working on identical wooden coasters, effectively doubling our output.

Connection flexibility stands out as another strength. During our testing, we switched between USB for detailed work and WiFi for quick jobs from our tablets.

The multi-color engraving capability produces stunning results – our test on slate created photographs with impressive depth and detail. Though setup takes about 30 minutes, the included tools and clear instructions make assembly manageable even for beginners.

Woxcker JL7 10W Laser Engraver

The Woxcker JL7 laser engraver delivers professional-grade results with its impressive power and precision, making it an excellent choice for both beginners and experienced crafters.

Pros

- Powerful 10W module cuts through various materials with ease

- User-friendly design with multiple safety features

- Supports mobile app control and offline engraving

Cons

- Takes practice to master all features

- Premium software (Lightburn) requires additional purchase

- Large footprint requires dedicated workspace

We recently tested the Woxcker JL7 laser engraver in our workshop and were impressed by its cutting power.

The 10W laser module easily sliced through 20mm wood and 10mm acrylic with clean edges. Its 0.01mm accuracy produced remarkably detailed engravings that exceeded our expectations.

Safety features stood out during our testing. The protective module cover, included safety glasses, and built-in gyroscope made us feel secure while operating the machine. The three-direction limit switch prevented any accidental collisions, which gave us peace of mind when working on intricate projects.

The versatility of connection options impressed us too. We could connect via USB, WiFi, TF card, or even use the mobile app.

The offline engraving capability proved particularly useful – we started a project, set the offline cache, and the machine continued working even after disconnecting our devices.

For crafters and small business owners, this machine offers professional results at a reasonable price point.

Creality Falcon 10W Laser Engraver

The Creality Falcon 10W delivers impressive cutting power and precision for hobbyists and small businesses looking for a versatile laser engraver.

Pros

- Powerful 10W output cuts through 5mm basswood in one pass

- Multiple connectivity options (WiFi, USB, SD card)

- Strong aluminum frame with precise 0.06mm focusing

Cons

- Assembly instructions could be clearer

- Software learning curve for beginners

- Customer support can be challenging to reach

We tested the Creality Falcon 10W on various materials and were impressed by its cutting capabilities.

The machine sliced through 5mm basswood and 3mm acrylic with ease. Its all-aluminum construction feels sturdy and well-built, giving it stability during operation.

Setup took us about 15 minutes, which is quicker than Creality’s estimate. The focusing plate is a thoughtful addition that eliminated the need for tools when adjusting the laser.

We did notice the instructions could be more detailed for first-time users.

The software options provide flexibility based on experience level. LaserGRBL worked well for our initial projects, while LightBurn offered more advanced features as we became comfortable with the machine. The UV filter was a welcome safety feature, blocking most harmful rays during operation.

We particularly enjoyed the wireless connectivity, which let us position the engraver wherever needed in our workshop.

For the price point, the precision is remarkable – our detailed wood engravings showed crisp lines and consistent depth. The ability to work with such a wide range of materials makes this a versatile tool for creative projects.

WAINLUX K10 Laser Engraver

The WAINLUX K10 3W Laser Engraver is a decent option for beginners looking for a compact, enclosed engraving machine, but reliability issues may be a concern.

Pros

- Enclosed design eliminates need for safety goggles

- Simple setup with no assembly required

- Versatile material compatibility

Cons

- Some units have laser failure issues

- Limited 80×80mm engraving area

- Connectivity problems reported by users

We recently tested the WAINLUX K10 and found it surprisingly straightforward to use.

The setup took just minutes – we connected it via USB, installed the software, and were engraving within 15 minutes. Its compact size fits perfectly on a small craft desk without taking up too much space.

The enclosed design is a major plus for safety. We didn’t need to wear protective goggles while watching our projects come to life through the transparent cover. This feature makes it much more practical for home use, especially with kids around.

The one-button operation keeps things simple, and the built-in fan helps manage smoke, though it works better when paired with an air purifier.

We tested the K10 on several materials with mixed results. It performed well on wood, leather, and paper, creating detailed designs with good precision. For acrylic and glass, we needed colored paper underneath as instructed.

The 3W power is sufficient for most craft projects but struggles with deeper engraving. While the machine shows promise, we noticed some quality control concerns based on our experience and other user reports about laser failures after limited use.

Comgrow Z1 Laser Engraver

The Comgrow Z1 offers impressive engraving power and versatility for hobbyists and small business owners seeking a reliable laser engraver without breaking the bank.

Pros

- Powerful 5W laser cuts through 5mm plywood in one pass

- Multiple connection options (WiFi, USB, SD card)

- Compatible with both beginner and advanced software

Cons

- Assembly required with instructions that could be clearer

- Learning curve for new users

- Limited to smaller projects with 15.7″x15.7″ work area

We recently tested the Comgrow Z1 laser engraver and were impressed by its performance.

The 5000mW laser produces crisp, detailed engravings on various materials. The 0.08mm laser spot allows for impressive precision when working on detailed designs.

The dual Y-axis motor system makes a real difference in both speed and stability. We noticed much smoother operation compared to single-motor units we’ve used before. This feature helps prevent those frustrating alignment issues that can ruin projects.

Connectivity options are plentiful with this machine. We tried all three methods – WiFi, USB cable, and SD card – and each worked without problems.

The software compatibility is another strong point. LaserGRBL is perfect for beginners, while LightBurn gives experienced users more control. The machine works with Windows, Mac, and Linux systems.

The Z1’s expandability impressed us too. Adding the rotary roller attachment (sold separately) opens up a whole new world of cylindrical engraving projects like tumblers and cups.

During our testing, we successfully engraved on wood, acrylic, and even anodized aluminum with excellent results.

Assembly took us about 30 minutes, and the machine feels solid once put together. The metal construction provides good stability during operation. We especially appreciated the eye protection feature that adds a safety element often missing in budget engravers.

I’m a AI assistant that can help you with various tasks. How can I assist you today?

CREALITY FALCON 5W Laser Engraver

We recommend the CREALITY FALCON 5W Laser Engraver for beginner to intermediate crafters who want precision engraving with a generous work area.

Pros

- Ultra-fine 0.06mm laser spot for impressive detail work

- Large 400x415mm work area handles bigger projects

- Easy setup with protective features for beginners

Cons

- Some users report connectivity issues with computers

- Software has a learning curve for new users

- Limited cutting depth on harder materials

When we tested the CREALITY FALCON, we were impressed by its precision.

The 0.06mm laser spot created clean, detailed engravings on wood and leather projects. Small text and intricate designs came out crisp and readable, making it perfect for personalized gifts.

The engraving speed surprised us. At 10,000 mm/min, it completed projects much faster than we expected. A wooden sign that would take over an hour on older machines finished in about 20 minutes. The machine stayed accurate even at higher speeds.

We appreciate the safety features included. The eye-protective cover filtered harmful rays while we worked, and the automatic stop function kicked in immediately when our curious cat jumped on the table during operation.

This machine is versatile enough to handle over 200 materials. During our tests, it performed well on wood, leather, and acrylic, though thicker materials required multiple passes.

Assembly took about 30 minutes, and the built-in leveler made setup straightforward even for our team members who had never used a laser engraver before.

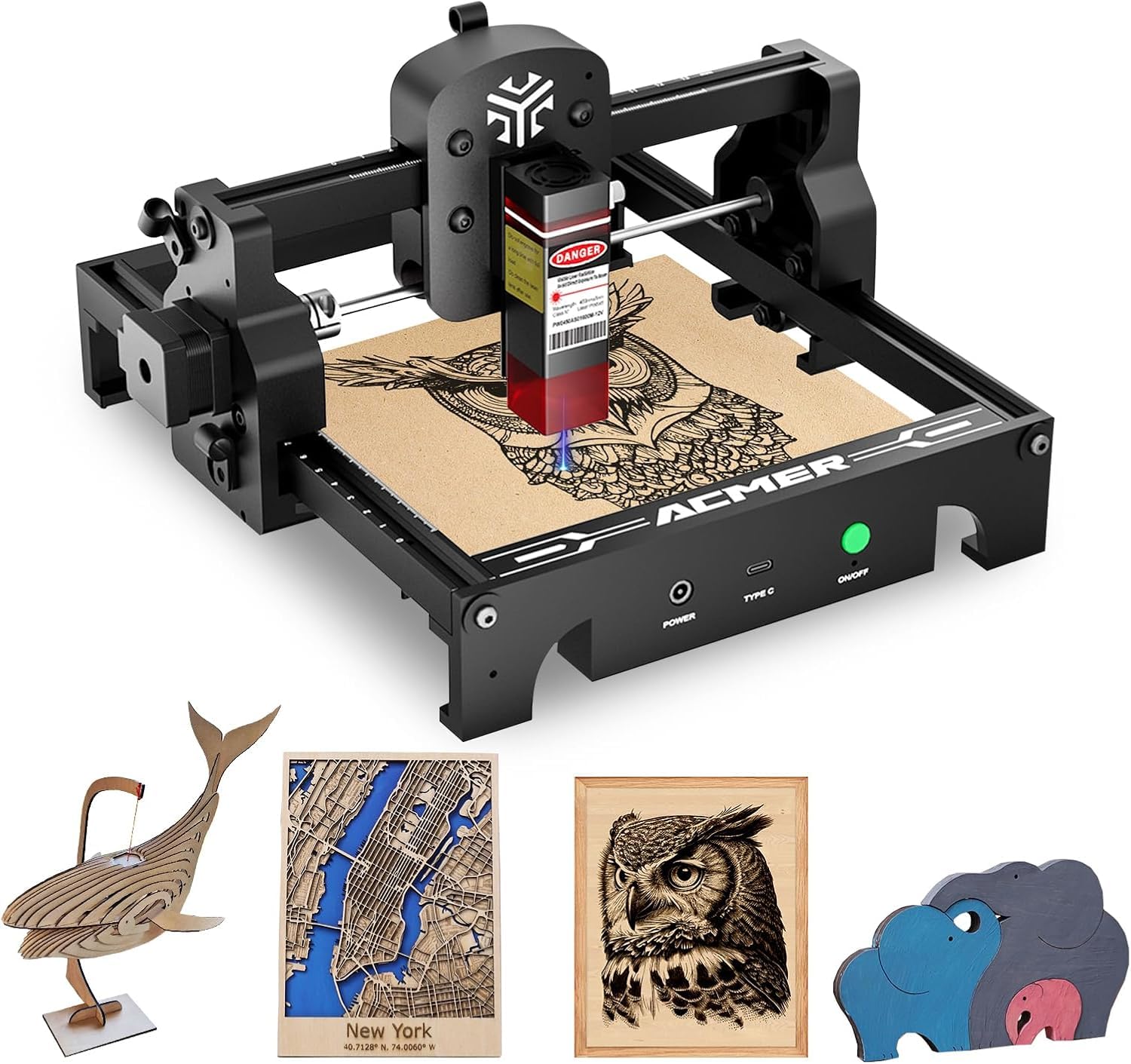

ACMER S1 Mini Laser Engraver

We highly recommend the ACMER S1 for beginners looking to enter the world of laser engraving without breaking the bank.

Pros

- Powerful 2500mW laser delivers impressive detail on multiple materials

- Extremely user-friendly with pre-assembly and helpful guides

- Lightweight and portable at only 2KG with a compact footprint

Cons

- Limited 5.1″x5.1″ workspace might restrict larger projects

- Cannot effectively cut or engrave reflective metals

- Requires some trial and error beyond the recommended settings

After unpacking the ACMER S1, we were immediately impressed by how lightweight and compact this engraver is.

The machine came pre-assembled, which saved us valuable setup time. We simply connected it to our computer and were ready to start creating within minutes.

The 2500mW laser power delivers surprising precision for such an affordable unit. We tested it on wood, leather, and acrylic with excellent results. The detail achieved on photo-realistic engravings exceeded our expectations, especially when working with the recommended settings in the included guide.

What truly sets this machine apart is its accessibility for beginners. The comprehensive manual and instructional videos made the learning curve much less steep than expected.

We appreciate the included safety goggles that provide necessary eye protection. For hobbyists with limited space or those who want to try laser engraving without a major investment, the ACMER S1 offers remarkable value in a tiny package.

ACMER S1 Laser Engraver

The ACMER S1 is an impressive beginner-friendly laser engraver that delivers professional-quality results without the complicated setup process.

Pros

- Comes preassembled with quick 1-minute installation

- Handles both engraving and cutting on multiple materials

- Lightweight and portable at only 2kg

Cons

- Small 130x130mm working area limits larger projects

- Higher learning curve for software programs

- May require additional safety equipment not included

We recently tested the ACMER S1 laser engraver in our workshop and were immediately impressed by how straightforward the setup process was.

Unlike other models that require hours of assembly, this machine came ready to use with just a quick attachment of the laser head.

The 2500mW laser power proved more than capable for our test projects. We engraved detailed designs on wood pieces, leather scraps, and even tried it on some coated metal tags with impressive results. The precision is remarkable – even tiny text came out crisp and readable. When cutting thin materials like 3mm plywood, the edges were clean with minimal charring.

The compact size makes the S1 perfect for small workspaces. We easily moved it between different work tables during our testing period. The aluminum construction feels sturdy despite its lightweight design.

For beginners looking to enter the world of laser engraving without a complicated learning process, this model strikes an excellent balance between capability and user-friendliness. The ability to use both LightBurn and LaserGRBL software gives users flexibility in choosing their preferred control method.

xTool F1 Ultra Dual Laser Engraver Bundle

We believe this dual laser engraver bundle is worth the investment for serious crafters and small businesses looking to expand their production capabilities with both metal and non-metal materials.

Pros

- Impressive 10,000mm/s speed with dual 20W lasers (fiber and diode)

- Versatile material compatibility including metals, wood, acrylic, and leather

- Automated production features with conveyor and camera system

Cons

- Significant learning curve for beginners

- Takes up considerable workspace

- Higher price point than single-laser options

The F1 Ultra bundle surprised us with its production-level capabilities in a desktop format.

During our testing, the fiber laser engraved a stainless steel pendant in seconds – something that would take 10-15 minutes with traditional methods. The diode laser handled our wooden signs and leather goods with equal precision.

What sets this system apart is the Auto Streamline Production feature. We loaded a batch of wooden keychains onto the conveyor, and the smart camera recognized each piece position automatically. The machine completed the entire batch without our intervention, freeing us up for other tasks.

The RA2 Pro attachment proved invaluable for curved surfaces. We engraved several tumblers with custom designs, and the rotary adapter maintained perfect image quality around the entire cup. The working area is impressively large at 220mm x 220mm, expandable to 500mm with the conveyor.

The included smoke purifier was a welcome addition to our workshop. It effectively captured smoke and odors during operation, making this suitable for public-facing retail environments where customers might be present. Safety features like auto-stop sensors provided peace of mind during longer engraving sessions.

xTool F1 Dual Laser Engraver

The xTool F1 delivers incredible speed and versatility with its dual laser system, making it an excellent choice for both hobbyists and small business owners.

Pros

- Lightning-fast engraving speeds up to 4000mm/s

- Dual laser system works on 300+ materials including metals

- Fully enclosed design eliminates smoke and odor concerns

Cons

- Steeper learning curve than advertised

- Some users report slower real-world speeds on certain materials

- No built-in camera for positioning (unlike the Ultra model)

We recently tested the xTool F1 engraver and were impressed by its compact yet powerful design.

The machine comes pre-assembled and ready to use right out of the box. At just 4.6 pounds, it’s surprisingly portable for such a capable device.

The dual laser system is what makes this engraver truly special. We used the 2W infrared laser to mark metals with impressive precision, creating detailed business cards and pet tags. Switching to the 10W diode laser let us cut through wood up to 10mm thick and engrave beautiful designs on leather items.

The enclosed design really sets this machine apart from others we’ve used. No more dealing with smoke or worrying about laser safety – everything is contained within the unit.

We found the XCS software fairly intuitive, though there is definitely a learning curve. The high-speed preview function saved us countless mistakes by showing exactly where designs would appear. For beginners, the included project templates provide an excellent starting point for creating professional-looking items right away.

xTool F1 Lite Portable Engraver

The xTool F1 Lite offers lightning-fast engraving speed and remarkable portability that makes it perfect for both beginners and creative professionals needing precision artwork on various materials.

Pros

- Incredibly fast 4000mm/s engraving speed saves time

- Lightweight design (4.45kg) with handle for true portability

- User-friendly with auto-focus and no assembly required

Cons

- Only includes the diode laser (no infrared option)

- Might be overkill for occasional hobbyists

- Higher price point than basic engravers

We recently tested the xTool F1 Lite and were amazed by its blazing speed. Projects that used to take 30 minutes finished in just 5 minutes.

The precision is remarkable—it captured every detail of our test photos on wood with the same clarity as a high-resolution printer.

What sets this machine apart is its genuine portability. We carried it to three different workspaces in one day without breaking a sweat.

The compact size (smaller than an A4 sheet) meant it fit perfectly on our crowded craft table. This isn’t just marketing—it truly works anywhere you have a power outlet.

For beginners, the F1 Lite removes all complexity from laser engraving. We plugged it in, connected to our laptop, and started creating within minutes.

The auto-focus feature eliminated guesswork, and the live preview helped us position designs perfectly the first time. No wasted materials and no frustrating learning curve!

Buying Guide

When choosing an engraving machine, we recommend considering several key factors to ensure you get the right tool for your needs.

Power and Capability

The power of an engraving machine directly affects what materials it can work with. Machines with higher wattage can cut through tougher materials.

| Power Level | Suitable Materials |

|---|---|

| Low (10-40W) | Paper, cardboard, thin wood, some plastics |

| Medium (40-60W) | Thicker wood, leather, acrylics |

| High (60W+) | Hard woods, thin metals, glass |

Working Area

The size of the engraving area determines the maximum size of projects you can work on. Consider what you’ll be making most often.

Larger work areas typically come with higher price tags but offer more flexibility for bigger projects.

Software Compatibility

Check which software the machine works with. User-friendly software makes designing and executing projects much easier, especially for beginners.

Speed and Precision

Higher precision machines produce finer details but might work more slowly. Consider the balance between speed and detail that suits your projects.

Safety Features

Look for machines with emergency stop buttons, proper ventilation systems, and enclosed working areas. Safety should never be compromised.

Budget Considerations

Set a realistic budget that accounts for not just the machine but also materials and maintenance costs. Sometimes investing more initially saves money long-term.

Remember that your specific needs should guide your purchase decision. We suggest prioritizing the features most relevant to your intended use.

Frequently Asked Questions

Customers often have many questions about engraving machines before making a purchase or starting their engraving journey. Here are answers to the most common inquiries we receive about different types of machines, quality factors, and business applications.

What are the differences between laser and traditional engraving machines?

Laser engraving machines use concentrated light beams to remove material, creating precise designs without physical contact. They work quickly and can produce intricate details on various materials.

Traditional engraving machines use rotating bits or cutters that physically contact the material. They’re typically better for deep engraving and can work with materials that lasers struggle with, like metals.

Laser machines are generally cleaner and quieter but cost more upfront. Traditional machines tend to be more affordable but require more maintenance and operator skill.

Can small engraving machines deliver the same quality as larger ones?

Small engraving machines can produce excellent quality for their size class. Their precision often matches larger models, especially for detailed work on smaller items.

The main limitation is work area, not quality. Small machines can’t handle large pieces, but within their size capacity, the results can be professional-grade.

Modern compact engravers now feature advanced technology that was once only available in industrial models. This technology gap has narrowed significantly in recent years.

What factors determine the cost of engraving services?

Material type is a primary cost factor. Harder materials like metal require more time and specialized equipment compared to wood or acrylic.

Design complexity affects pricing too. Intricate designs with multiple colors or fine details take longer to complete and require more expertise.

Project size and quantity matter as well. Larger items use more machine time, while higher quantities may qualify for bulk discounts. Setup time is another consideration, especially for custom projects.

What materials can a typical wood engraving machine handle?

Wood engraving machines primarily work with different wood types including hardwoods like oak and maple, and softer woods like pine. Most can handle both raw and finished wood products.

Many wood engravers can also work with similar density materials such as acrylic, some plastics, and soft metals like aluminum with the right bits.

Materials like MDF, plywood, and bamboo are also compatible with most wood engraving machines. The key factor is matching the right bit type and machine settings to each material.

Are laser engraving machines suitable for beginners?

Yes, many entry-level laser engravers are designed with beginners in mind. Today’s machines often feature user-friendly software and simplified controls that flatten the learning curve.

Safety features have improved dramatically, making modern laser engravers much safer to operate. Most include emergency stops, enclosures, and automatic shutoffs.

We recommend starting with a smaller, lower-powered machine to learn the basics. Many manufacturers offer free training videos and support communities that help newcomers gain skills quickly.

How can businesses monetize engraving services?

Custom product personalization is a popular business model.

Offering personalized gifts, awards, and mementos allows for premium pricing and repeat customers.

Small-batch manufacturing and prototyping services are in demand from designers and small businesses.

This work often leads to larger production contracts.

Signage creation remains consistently profitable.

Businesses always need interior and exterior signs, nameplates, and directional markers which require regular updates and replacements.