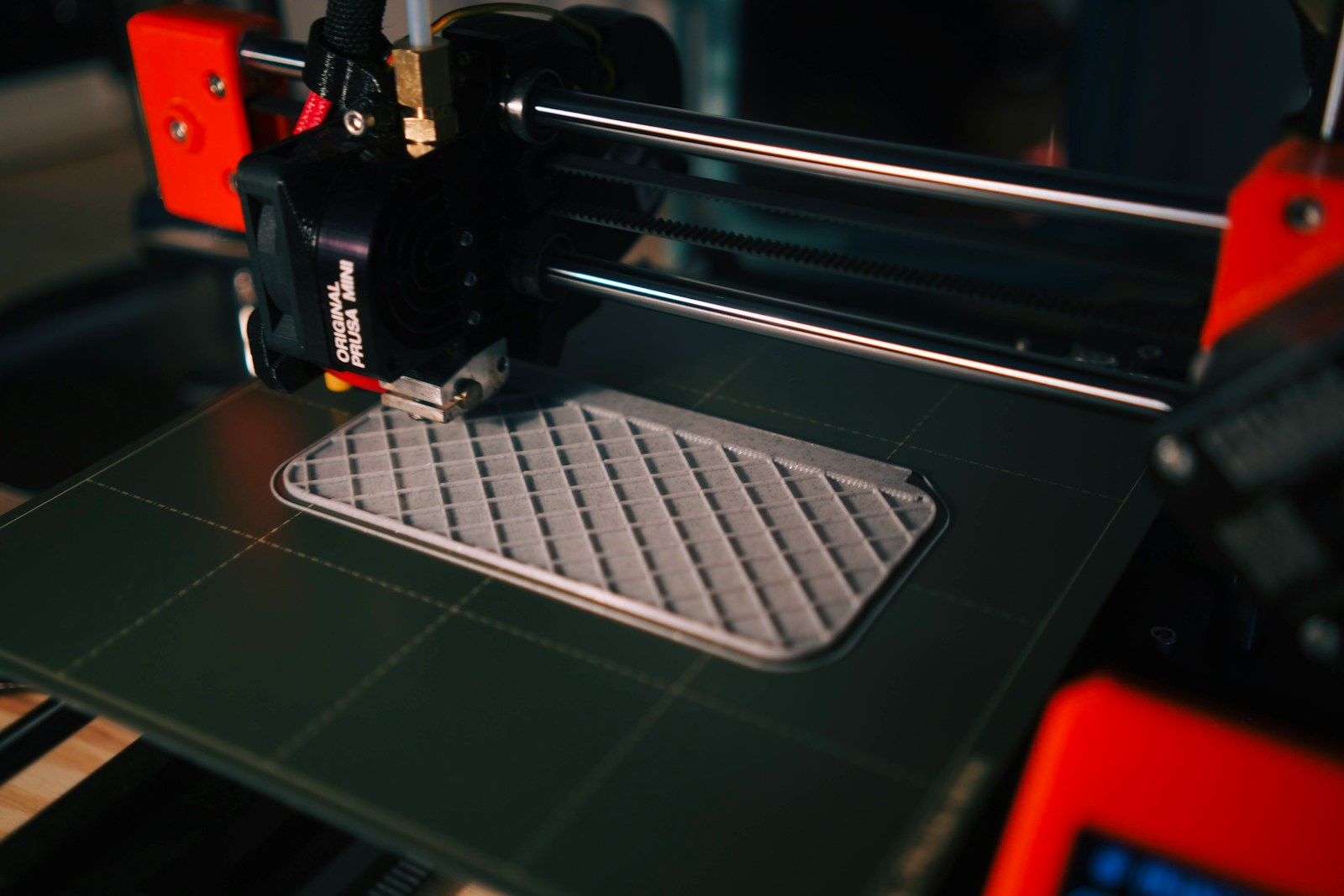

The 3D printing industry is entering a golden era. Once a niche innovation used mostly for prototyping, 3D printing—or additive manufacturing—is now poised to become a cornerstone of global production. According to recent projections, the market is expected to surge from $29.29 billion in 2025 to a staggering $186.4 billion by 2033. That’s a compound annual growth rate (CAGR) of roughly 21%, reflecting a massive shift in how the world manufactures, designs, and delivers products.

Why 3D Printing Is Booming

This explosive growth isn’t just hype—it’s rooted in real transformation across multiple sectors. As industries embrace digitization, 3D printing offers unmatched advantages: rapid prototyping, reduced material waste, highly customizable designs, and decentralized production. The convergence of technologies—like artificial intelligence, machine learning, and the Internet of Things (IoT)—is also amplifying what’s possible with modern printers. For example, AI is being used to optimize print paths, improve quality assurance in real time, and even design parts that were previously too complex for traditional methods.

Democratization of Manufacturing

One of the most disruptive aspects of this growth is how 3D printing is leveling the playing field. Small startups can now compete with major manufacturers using compact yet powerful printers that cost a fraction of traditional equipment. This democratization is enabling rapid innovation across fields like biomedical engineering, architecture, robotics, and even fashion.

Expect to see more localized, just-in-time manufacturing models, where businesses can print parts and products closer to the point of use—cutting down on logistics costs and carbon emissions in the process. This shift not only supports sustainability but also enhances supply chain resilience, which has become a strategic priority after the disruptions caused by global events in recent years.

Key Drivers of Market Growth

Industrial Adoption

Industries like aerospace, automotive, and medical device manufacturing are leading the charge. In aerospace, for instance, companies like GE Aviation and Boeing are printing lightweight engine components that reduce fuel consumption. In healthcare, custom prosthetics, dental aligners, and even bioprinted tissues are rapidly becoming the norm.

Technological Advancements

Materials science is evolving rapidly, with newer materials like carbon fiber composites, bio-inks, and high-strength alloys unlocking new applications. Meanwhile, printing speeds are accelerating thanks to breakthroughs like Continuous Liquid Interface Production (CLIP) and Multi Jet Fusion (MJF), making 3D printing viable for full-scale manufacturing.

Customization and On-Demand Production

Consumers and businesses alike are drawn to the promise of tailor-made solutions. Whether it’s a custom-fit bicycle frame or an on-demand spare part, 3D printing makes mass customization scalable.

Market Breakdown

| Segment | Details |

|---|---|

| By Component | Hardware leads with over 52% market share, driven by demand for industrial-grade printers. |

| By Application | Prototyping accounts for 54% of market use, essential in product development cycles. |

| By Material | Metals dominate for their durability and precision in engineering-heavy sectors. |

Regional Outlook

| Region | Highlights |

|---|---|

| North America | Currently leads the global market, backed by early adoption and R&D investments. |

| Asia-Pacific | Fastest-growing region with a projected 22% CAGR, thanks to booming manufacturing hubs in China, India, and Southeast Asia. |

Europe also remains a strong contender with robust adoption in Germany, the UK, and France—driven by both industrial demand and supportive government initiatives.

Looking Ahead

The 3D printing market is more than just a hot trend—it’s a fundamental shift in how things are made. From aerospace and automotive to fashion and food, additive manufacturing is rewriting the rules of production. With scalability, cost efficiency, and environmental advantages, it’s not hard to see why investors, entrepreneurs, and engineers are betting big on a future built—layer by layer—with 3D printing.

Key Takeaways

- The 3D printing market is on track to jump from $29.29 billion to over $186 billion by 2033, thanks to digitization and Industry 4.0.

- AI is making waves, and new uses in healthcare, aerospace, and consumer goods are speeding up growth.

- As 3D printing gets more accessible, it’s spawning new business models and disrupting the old ways of making things.

Key Growth Drivers of the 3D Printing Market

The 3D printing world is on a tear, and it’s not just hype—there are some real, tangible reasons behind it. These drivers aren’t just changing how stuff gets made; they’re actually opening up new doors for businesses everywhere.

Technological Advancements in 3D Printing

Material science is probably the unsung hero here. With new advanced polymers, metals, ceramics, and composites, 3D printers can now spit out parts that are tougher and more useful than ever.

Print speeds? They’ve gone from “go get a coffee and come back” to “wait, it’s done already?” Some newer systems are up to 25-100 times faster than the old ones, so mass production isn’t just a pipe dream anymore.

Printers are also getting crazy precise—think tolerances down to 10 microns. That opens the door for stuff in healthcare and aerospace where you just can’t afford to be sloppy.

Multi-material printing is another leap. Now, you can print one object with different materials baked in, each with its own properties. Try pulling that off with traditional manufacturing—good luck.

Industry Adoption Across Manufacturing Sectors

Aerospace has gone all-in. Boeing? They’re using over 70,000 3D-printed parts in their planes. That’s not a typo.

Automotive giants like BMW and Ford are using additive manufacturing not just for prototyping, but for actual production parts and custom tools.

Healthcare’s probably one of the most exciting spaces. We’re talking patient-specific implants, surgical models, even bioprinted tissue. The medical 3D printing market alone could blow past $3.5 billion by 2026.

Consumer goods? 3D printing is letting companies get products to market faster and make custom stuff people actually want. That’s a win-win.

Demand for Customized Production Solutions

Mass customization is finally real. Companies can churn out personalized products at scale, which is honestly what consumers have been asking for all along.

On-demand production means you don’t need massive warehouses full of unsold inventory. Just print what you need, when you need it.

Designers aren’t boxed in by old limitations anymore. Wild, complex shapes that used to be impossible (or way too expensive) are now totally doable.

And let’s not forget supply chain resilience. After the past few years, the ability to make stuff locally and pivot quickly isn’t just nice—it’s essential.

Government Initiatives and Investments

Governments are throwing serious money at this. In the U.S. alone, over $200 million has gone into additive manufacturing programs like America Makes.

Tax breaks and incentives are making it easier for smaller businesses to jump in. That’s helping level the playing field a bit.

Education is getting a boost too. More universities and tech schools are building out 3D printing programs, with government backing.

And these public-private partnerships? They’re creating hotspots for innovation, where new ideas and tech actually get off the ground instead of dying in a lab somewhere.

Market Projections and Revenue Trends

The 3D printing market is showing some seriously impressive numbers, no matter which analysis you read. Forecasts aren’t always in perfect agreement, but the direction is crystal clear: up, and fast.

Revenue Growth Analysis Through 2033

Financially, things are ramping up. In 2023, the market was pegged at about $20.37 billion. Now, projections for 2033-2034 are all over the map—from $134.58 billion to $186.4 billion—but either way, it’s a huge leap.

Depending on which source you trust, the compound annual growth rate (CAGR) is somewhere between 16.4% and 23.5%. Sure, that’s a big range, but it just shows how many moving parts there are.

Some reports see the market hitting $37.4 billion by 2029. Others think the U.S. alone will hit $41.4 billion by 2033. However you slice it, there’s a lot of money flowing into this space.

Regional Market Leaders

The U.S. is out in front, no question. The American market hit $5.8 billion in 2024 and could grow at a 21.7% CAGR through 2033. That’s fast.

Europe isn’t far behind, especially in manufacturing and healthcare. Germany, the UK, and France are putting serious resources into this tech.

Asia-Pacific is the one to watch for sheer speed. China and Japan are making huge strides, and it feels like every month there’s a new announcement from that region.

Where you see strong manufacturing, tech hubs, and government investment, you’ll find 3D printing taking off.

Forecasts for Segment-Specific Expansion

Hardware is still the big dog in the market—printer sales and equipment are what get things started in new areas.

Materials are catching up quick. Specialty filaments, resins, and powders are popping up to serve all kinds of industries, from cars to healthcare.

But the real rocket fuel? Software and services. Design platforms, cloud manufacturing, and on-demand printing services are set to grow even faster, and they keep the revenue flowing.

Growth rates by industry are all over the place:

- Healthcare: 25-30% CAGR

- Aerospace: 20-22% CAGR

- Automotive: 18-20% CAGR

- Consumer goods: 15-18% CAGR

Industry Impact and Applications

3D printing has honestly changed the game in a bunch of sectors. Its flexibility and ability to make custom stuff have made it especially valuable for industries that need precision or one-off solutions.

Healthcare and Medical Innovation

Healthcare’s gone all-in on 3D printing for patient-specific implants, prosthetics, and anatomical models. Surgeons are now using detailed 3D prints to plan out tricky procedures—which saves time in the OR and leads to better outcomes.

Key Medical Applications:

- Custom prosthetics that actually fit

- Dental aligners and implants tailored for each patient

- Pharmaceutical research, especially with drug delivery systems

- Bioprinting tissues (and maybe organs, someday?)

Hospitals can now make medical devices on-site, cutting down on supply chain headaches. During COVID-19, 3D printers cranked out ventilator parts and PPE when traditional suppliers couldn’t keep up.

Medical 3D printing is growing even faster than the overall market—22.3% CAGR through 2030, if you believe the projections.

Aerospace and Automotive Integration

Aerospace and car makers are using 3D printing for lightweight parts that just can’t be made any other way.

Boeing and Airbus have both loaded their aircraft with thousands of 3D-printed parts—sometimes 30-55% lighter than the old-school versions, but just as strong.

In the auto world, you’ll see:

- Rapid prototyping for design tweaks

- Custom tooling for assembly lines

- End-use parts in high-performance vehicles

- Replacement bits for vintage cars (which is honestly pretty cool)

Formula 1 teams? They’re printing parts trackside and making tweaks in real time. And the big automakers have sunk billions into additive manufacturing to speed up production.

Consumer Products and Emerging Verticals

Consumers are getting a taste of 3D printing in fashion, furniture, and home goods.

Customization is the name of the game—personalized shoes, jewelry, eyewear. Adidas and Nike have both dropped sneakers with 3D printed midsoles, and jewelers are making stuff that’s impossible to do the old-fashioned way.

Architecture firms are using 3D printing for detailed models and even actual building components. There are already fully 3D printed buildings in a few countries, which is kind of wild.

Education’s getting in on the act, too. More schools have 3D printers in their STEM programs, letting students get hands-on with design and manufacturing before they even hit the job market.

Challenges, Opportunities, and Future Outlook

The 3D printing space isn’t all smooth sailing—there are definitely some bumps in the road. But for anyone willing to tackle the challenges, there’s a ton of upside.

Barriers to Widespread Adoption

Upfront costs are still a big “yikes” for a lot of businesses. Industrial printers can run from $50,000 to several million bucks, which isn’t pocket change for small companies.

There are also technical speed bumps. Print speeds still can’t match traditional manufacturing for huge orders, and some materials need post-processing, which adds time and headaches.

Standardization is lagging. Without universal quality standards or certifications, industries like aerospace and healthcare can’t just jump in with both feet.

And don’t forget the talent gap. Designing for additive manufacturing and running advanced printers takes know-how that’s still pretty rare in the workforce.

Sustainability and Environmental Considerations

On the plus side, 3D printing can slash material waste by 70-90% compared to subtractive methods. That’s a big deal for sustainability.

But energy use is a sticking point. Some industrial printers, especially those working with metals, are real power hogs. There’s ongoing research into making them more efficient, but it’s not there yet.

Plastic filament? It’s a mixed bag. Most of it’s still petroleum-based, but we’re seeing more biodegradable and recycled options hit the market.

Local manufacturing means less shipping, which cuts down on emissions. That lines up with what consumers want—greener supply chains and less waste.

Opportunities for Market Stakeholders

Customization at scale is a goldmine. From medical devices to consumer goods, companies can offer personalized stuff without the usual cost headaches.

Supply chain resilience has become a buzzword for a reason. With 3D printing, companies can make parts on-demand and aren’t as tied to far-flung suppliers.

Material innovation is opening up new frontiers. Advanced composites, ceramics, and biomaterials are making it possible to 3D print things that just weren’t possible before.

Service-based models are booming. Instead of selling hardware, some companies are finding their niche by offering 3D printing as a service, consulting, or training—making it easier for others to get started.

Frequently Asked Questions

The 3D printing market is on a serious growth curve, with new tech and adoption popping up everywhere. Here’s a quick hit of answers to some of the most common questions about where this industry’s headed.

What are the key factors driving the growth in the 3D printing market?

A few things are really pushing the 3D printing market forward lately. First off, there’s just a huge wave of digitization happening everywhere, and all those buzzwords—like Industry 4.0—aren’t just hype anymore. These tech shifts are making 3D printing not just possible, but actually practical for a ton of different uses.

People are also way more into customization and on-demand production these days. Companies are starting to see the perks of making products that are tailored for their customers, and doing it quickly, too.

Plus, there’s been some real progress with printing materials and the tech itself. 3D printing systems can do things now that would’ve sounded impossible a few years back—stuff you just couldn’t pull off with old-school manufacturing.

How is the 3D printing market expected to evolve by 2033?

If you look at the numbers, the 3D printing market is expected to blow past USD 135.4 billion by 2033. That’s a pretty wild jump from the estimated USD 29.29 billion in 2025.

The market’s cruising along at a compound annual growth rate (CAGR) of about 16.4% between 2024 and 2029. That kind of momentum isn’t easy to ignore—clearly, more and more industries are hopping on board.

Of course, not every region grows at the same pace. For example, the U.S. market alone could hit around USD 34.28 billion by 2034, up from just USD 5.93 billion in 2024. That’s a big leap in just a decade.

Which industries are most significantly impacted by advancements in 3D printing technology?

Healthcare’s probably the most obvious one—you’ve got custom prosthetics, implants, and even bioprinted tissues now. It’s honestly changed the game for patient care and treatment options.

Then there’s aerospace and automotive. They’re using 3D printing to make lighter parts and to prototype new designs fast. That means better fuel efficiency and way shorter product development cycles.

Consumer goods companies are also getting in on the action. With 3D printing, customized products and small-batch runs are suddenly doable and affordable. It’s shaking up how products are designed and made, no question.

What are the latest trends influencing the global 3D printing industry?

Metal 3D printing is having a bit of a moment. The tech’s getting better and, importantly, cheaper—so industries that used to stick with plastics are starting to branch out.

Sustainability is another biggie. There’s a real push for eco-friendly materials—think biodegradable filaments and recycled stuff. Manufacturers who care about the environment are paying attention.

And let’s not forget the tech mashups. When you combine 3D printing with AI or IoT, you get these smart printing ecosystems that can spot issues and boost production efficiency. It’s pretty cool, honestly.

How does the market share of 3D printing vary by region or country?

Right now, North America’s leading the pack—especially the U.S., which seems to have a knack for adopting new tech early and throwing plenty of money at R&D.

Asia-Pacific, though, is catching up fast. Countries like China are manufacturing powerhouses, and there’s a lot of government support for advanced manufacturing. Southeast Asia’s emerging markets are starting to make waves, too.

Europe’s no slouch either, particularly when it comes to industrial 3D printing. Places like Germany and the UK are all about precision engineering and medical applications, which has kept them right in the thick of things.

What is the projected economic impact of 3D printing on manufacturing and supply chains?

3D printing, honestly, looks set to shake up supply chains by making things a bit simpler—and cheaper—thanks to more localized production. If you think about it, less stuff needs to be shipped long distances, and companies might not have to keep quite so much inventory lying around.

With the whole on-demand manufacturing thing, we’re probably going to see less waste and fewer piles of unused products. Being able to print parts only when you actually need them? That could really cut back on those massive warehouses filled with who-knows-what.

Of course, the job market won’t escape untouched. There’ll be new gigs popping up in 3D design, print operation, and developing new materials. But let’s be real, some traditional manufacturing jobs will have to adapt—maybe even blend old skills with the new tech. Change always finds a way, doesn’t it?